A screw conveyor is a continuous conveying machine that uses rotating spiral blades to propel material forward within a closed trough. It is primarily used to transport various bulk materials in powdered, granular, and small pieces, such as pulverized coal, flour, cement, grain, and fertilizer. It is an indispensable general-purpose conveying equipment in modern industrial production.

Content

1. Working Principle of a Screw Conveyor

A motor drives a central screw shaft at high speed through a reducer.

The spiral blades welded to the shaft rotate accordingly.

After material is added through the feed port, it fills the spaces between the blades.

Due to the material's own gravity and friction with the trough walls, it does not rotate with the spiral blades. Instead, it is pushed axially by the rotating blades, like a "nut," toward the discharge port.

Finally, the material is discharged at the discharge port at the other end, completing the conveying process.

The entire conveying process takes place within a closed trough, effectively preventing dust from flying, protecting the environment and the health of operators.

2. Main Types and Characteristics of Screw Conveyors

Based on their installation method and purpose, screw conveyors are primarily classified into the following categories:

Horizontal Screw Conveyor:

The most common type features a screw shaft positioned horizontally or slightly inclined (usually less than 20 degrees).

This type is suitable for conveying most powdered and granular materials horizontally or at a slight angle over short distances. Its simple structure makes it the most widely used.

Vertical Screw Conveyor:

The screw shaft is mounted vertically and is primarily used for lifting materials.

The operating principle is slightly different from the horizontal type. When the material is pushed to a certain height, its gravity and the friction generated by the blades balance, causing the material to rotate with the blades and not fall. At this point, the centrifugal force of the material plays a crucial role, throwing it against the pipe wall, where it is then pushed upward by the following blades.

This type is used in applications where materials need to be lifted to higher locations, such as in granaries and feed towers.

Flexible Screw Conveyor:

The screw is made of a special flexible material and structure, allowing the entire conveyor to bend and bypass obstacles. It is suitable for applications requiring complex circuits and flexible layouts, and is commonly used for feeding equipment such as packaging machines and injection molding machines.

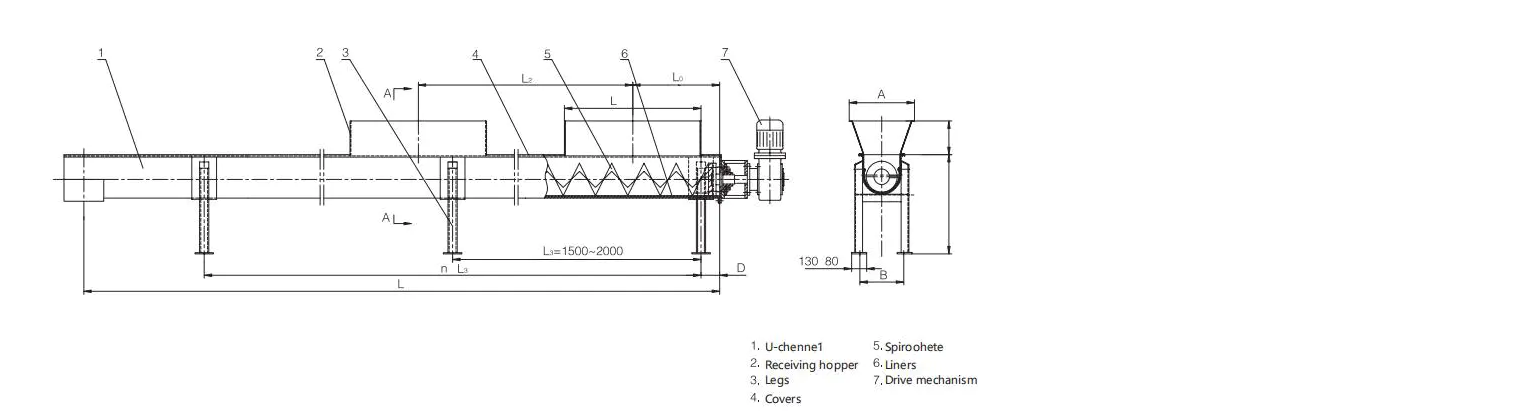

3. Core Structural Components

A typical screw conveyor generally consists of the following major components:

Drive: This includes a motor and a reducer, and is the power source for the machine, providing the power for the rotation of the screw shaft.

Screw: This is the core working component of the machine, consisting of a mandrel and welded spiral blades. The blade shape (such as solid surface, belt surface, or vane surface) is selected based on the material characteristics.

Bearings: These include head bearings, tail bearings, and intermediate suspension bearings. They support the screw shaft and ensure smooth rotation. Intermediate bearings are crucial for reducing screw shaft sag during long-distance conveying.

Trough: This is typically a U-shaped trough or a round tube, used to contain the material and screw, preventing dust leakage and spillage.

Inlet and outlet: These are the inlet and outlet for the material. Inlets and outlets can be located at multiple locations within the trough as needed, enabling multi-point loading and unloading, providing flexibility in process layout.

4. Advantages and Limitations

Advantages:

Simple structure: Low cost, easy to manufacture, install, and maintain.

Good sealing: Enclosed conveying effectively prevents dust contamination and material spillage, meeting environmental protection requirements.

High flexibility: The feed and discharge ports can be set in multiple locations, allowing one device to serve multiple process points.

High operability: Mixing, stirring, cooling, and other process operations can be performed simultaneously during the conveying process, making the machine multi-functional.

Small footprint: The small cross-sectional area allows for flexible placement in confined spaces.

Limitations:

Fragile materials: The relative motion between the blades and the material, as well as the compression between the materials, may cause some brittle materials to break.

High power consumption: Friction between the material and the blades and trough walls results in high energy consumption, making it unsuitable for ultra-long-distance conveying.

Material requirements: It is not suitable for conveying highly viscous, easily agglomerated, or entangled materials (such as asphalt and dough). These materials will adhere to the blades and shaft, causing blockage and affecting conveying efficiency. Limited conveying distance: The conveying length of a single machine generally does not exceed 70 meters, otherwise there will be too many intermediate suspension bearings, the resistance will be too large, and the energy consumption will increase dramatically.