| Model | QBGH-YR10000 | QBGH-YR15000 | QBGH-YR20000 | QBGH-YR25000 | QBGH-YR30000 | |

| Standard water removal | kg/24h | 10000 | 15000 | 20000 | 25000 | 30000 |

| Water removal capacity | kg/24h | 416 | 624 | 832 | 1040 | 1248 |

| Rated standard operating power | KW | 34 | 48 | 62 | 76 | 90 |

| Power distribution power | KW | 44 | 60 | 74 | 91 | 108 |

| Standard heating power | KW | 360 | 540 | 720 | 900 | 1080 |

| Number of modules | 4 | 6 | 8 | 10 | 12 | |

| Hot water flow rate | m3/h | 15.6 | 23.4 | 31.2 | 39 | 46.8 |

| Standard cooling power | KW | 320 | 480 | 640 | 800 | 960 |

| Cooling water flow rate | m³/h | 23 | 34.5 | 46 | 57.5 | 69 |

| Number of modules | set | 6 | 8 | 10 | 12 | 14 |

| Dimensions | m | 8.05×3.06×2.75 | 11.3×3.06×2.75 | 14.55×3.06×2.75 | 17.8×3.06×2.75 | 21.05×3.06 × 2.75 |

| Structural form | Assemble | Assemble | Assemble | Assemble | Assemble | |

| Unit weight | kg | 8600 | 12300 | 14800 | 16500 | 20400 |

| Standard heating working condition | 85°C/65°C (hot water, etc.) | |||||

| Standard cooling working condition | 33°C/45°C(Cooling water)(△t=12°C) | |||||

| Standard drying temperature | 50~65°C(Return air)/68~85°C(Air supply) | |||||

| Control system | Touch screen + PLC programmable control | |||||

| Model | QBGH-YR35000 | QBGH-YR40000 | QBGH-YR45000 | QBGH-YR50000 | |

| Rated standard water removal | kg/24h | 35000 | 40000 | 45000 | 50000 |

| Rated standard water removal | kg/h | 1458 | 1667 | 1875 | 2083 |

| Rated standard operating power | KW | 104 | 118 | 132 | 146 |

| Distribution power | KW | 125 | 142 | 158 | 175 |

| Standard heating power | KW | 1260 | 1440 | 1620 | 1800 |

| Number of modules | 14 | 16 | 18 | 20 | |

| Hot water flow rate | m3/h | 54.6 | 62.4 | 70.2 | 78 |

| Standard cooling power | KW | 1120 | 1280 | 1440 | 1600 |

| Cooling water flow | m³/h | 80.5 | 92 | 103.5 | 115 |

| Number of modules | set | 16 | 18 | 20 | 22 |

| Dimensions | m | 24.3 × 3.06 × 2.75 | 27.55 × 3.06 × 2.75 | 30.8×3.06×2.75 | 34.05 × 3.06×2.75 |

| Structural form | Assemble | Assemble | Assemble | Assemble | |

| Unit weight | kg | 23400 | 26300 | 29300 | 32200 |

| Standard heating conditions | 85°C/65°C (hot water, etc.) | ||||

| Standard cooling conditions | 33°C/45°C(Cooling water)(△t=12°C) | ||||

| Standard drying temperature | 50~65°C(Return air)/68~85°C(Air supply) | ||||

| Control system | Touch screen + PLC programmable control | ||||

*The rated standard water removal volume varies due to mud properties, molding conditions, dust, etc. Please consult an engineer for details.

Just say hello and we'll start a fruitful collaboration. Start your own success story.

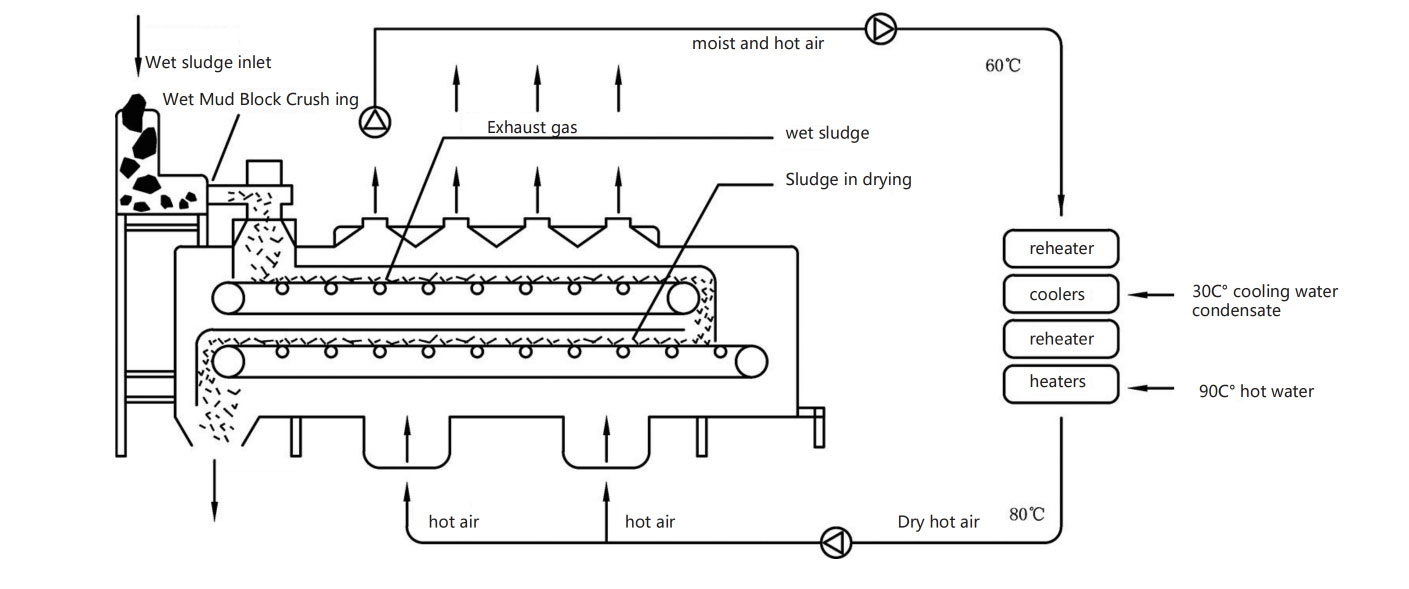

Driven by the "dual carbon" strategy, the low-temperature waste heat sludge dryer takes energy recycling as the core and creates a new paradigm of "waste treatment with waste" in the field of sludge treatment. This equipment captures waste heat in industrial processes and builds a system from heat recovery to resource regeneration, transforming the traditional high-energy-consuming sludge drying process into a sustainable low-carbon solution, providing an innovative path for the coordinated governance of industrial ecology.

Its core technology lies in the deep coupling of waste heat cascade utilization and dynamic drying. The equipment recovers waste heat emitted from generator sets or chemical reactions through an efficient heat exchange system, and converts it into a drying medium after being heated by a heat pump. Water evaporates under a low temperature gradient, avoiding the decomposition of organic matter caused by high temperature, and deep dehydration is achieved through humidity difference.

The equipment design fully integrates the concepts of intensiveness and intelligence. The modular structure can flexibly adapt to the characteristics of waste heat sources in different scenarios. Whether it is flue gas waste heat, steam condensate or cooling circulating water, it can be converted into drying kinetic energy through customized heat exchange units. The dual leap in environmental benefits and resource value is the core breakthrough of this technology. The moisture content of the dried sludge has decreased, realizing the value transformation from waste to building materials

With the deep integration of the industrial Internet and the energy system, the low-temperature waste heat sludge dryer is evolving from a single device to a smart energy node. This technological evolution contributes innovative samples to the global industrial low-carbon transformation.