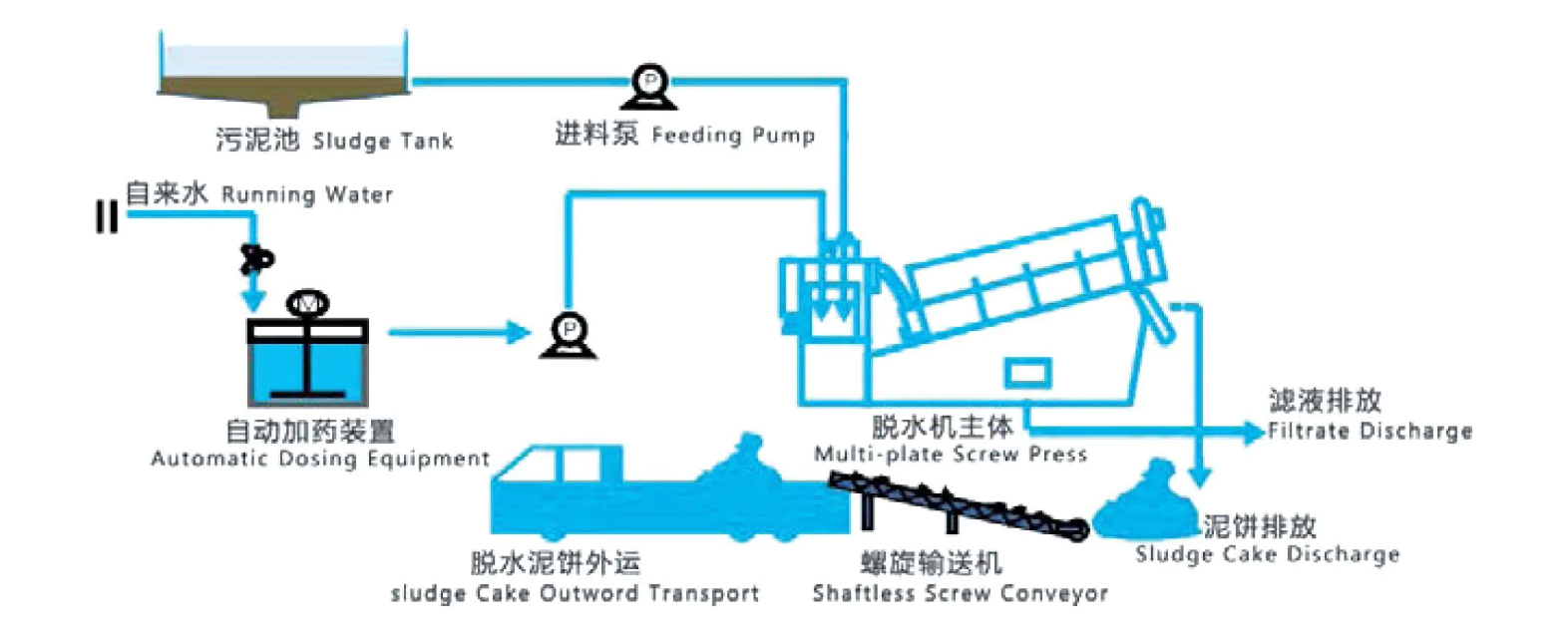

A screw press sludge dewatering machine is a mechanical device used to dewater sludge during sewage treatment. It combines the principles of screw extrusion and disc filtration to physically separate water from sludge, thereby reducing sludge volume. The screw press sludge dewatering machine achieves efficient flocculation under automated operation, continuously concentrating, squeezing, and dewatering the sludge, and then returns or discharges the collected filtrate.

Content

1. Working Principle of the Screw Press Sludge Dewatering Machine

Screw Shaft and Disc Structure:

The core of the device consists of a screw shaft and multiple stacked fixed and moving rings (discs). As the screw shaft rotates, it propels the sludge forward, while the gaps between the discs gradually narrow, continuously squeezing the sludge.

Three-Step Dewatering Process:

Concentration Stage: After the sludge enters the machine, it is initially concentrated by the screw shaft, and free water is filtered out through the gaps between the discs. Dewatering Section: Sludge is pushed into a narrow section, where it is squeezed by the screw shaft and the stacked discs, further removing moisture.

Compression Section: With minimal clearance, the sludge is forcefully compressed into a cake, reducing its moisture content to below 80%.

Self-Cleaning Function:

The relative movement between the stacked discs (moving and fixed rings) creates friction, preventing filter clogging and reducing the frequency of manual cleaning.

2. Main Components

| Components | Function |

| Screw Shaft | Rotates to push sludge, providing extrusion power. Typically made of wear-resistant alloy |

| Lamination Pack | Alternating fixed and rotating rings create the filter gap. Typically made of stainless steel or special plastic |

| Drive Unit | Motor + reducer controls screw shaft speed (typically 1-5 rpm, adjustable) |

| Filtrate Collection Tank | Collects extruded water and returns it to the sewage treatment system |

| Flushing System | Optional high-pressure water flushing device prevents sludge from adhering |

3. Selection Considerations

Sludge Properties: Test the sludge for viscosity, solids content, and organic matter content.

Processing Capacity: Select a model based on the average daily sludge volume, with a 20% margin recommended.

Material: For corrosive sludge, use 316 stainless steel or specially coated laminates.

Ancillary Equipment: Determine whether a flocculant dosing system, sludge transfer pump, etc. are required.

4. Maintenance Tips for Screw Press Sludge Dewatering Machine

(1) Daily maintenance (every shift/day)

Operation status monitoring: Check whether the motor current and screw shaft torque are within the rated range (abnormal increase may indicate blockage or wear). Observe the water content of the sludge. If it suddenly increases, check the gap between the stacking plates or the change in the sludge properties. Monitor the noise of the equipment. Abnormal vibration or metal friction may indicate bearing damage or screw shaft offset.

Filtrate observation: When the turbidity of the filtrate increases, it may be due to blockage or wear of the stacking plates, resulting in poor sealing. It is necessary to stop the machine for flushing or check the stacking plates.

Lubrication point inspection: Manual lubrication equipment requires daily addition of grease (such as lithium-based grease) to the screw shaft bearings and drive chain.

(2) Regular maintenance (weekly/monthly/quarterly)

1). Weekly maintenance

Flushing system inspection: Test whether the high-pressure flushing water nozzle is unobstructed (especially after processing sticky sludge) to prevent stacking scale.

Clean the sediment in the filtrate collection tank to avoid secondary pollution.

2) Monthly Maintenance

Lamination Stack Cleaning: After shutting down, manually rotate the screw shaft and use a high-pressure water gun (pressure ≥ 3 MPa) to flush the gaps between the laminations from the mud outlet to remove trapped sludge.

Lamination Wear Inspection: If the fixed/rotating rings show obvious scratches or deformation, they should be replaced (stainless steel laminations typically have a lifespan of 3-5 years).

Seal Inspection: Replace easily aged seals, such as shaft seals and pipe flange gaskets, to prevent water and mud leakage.

3) Quarterly Maintenance

Key Component Disassembly and Inspection: Remove the screw shaft and inspect the wear-resistant bushing for wear (wear > 2 mm requires replacement).

Calibrate the concentricity of the screw shaft and laminations; any offset > 0.5 mm requires adjustment.

Gearbox Maintenance: Change the gear oil (after the first 500 hours of operation, and every 3,000 hours or six months thereafter).