Content

What is a Screw Press Sludge Dewatering Machine?

A screw press sludge dewatering machine is a type of equipment used in wastewater treatment plants to separate water from sludge, reducing its volume and improving its handling and disposal. This process helps in the efficient management of wastewater by extracting moisture from sludge, turning it into a more solid, manageable form that can be further treated or disposed of safely. The machine uses a screw mechanism that gradually presses the sludge to expel excess water, ensuring effective dewatering with minimal energy consumption.

How Does a Screw Press Sludge Dewatering Machine Work?

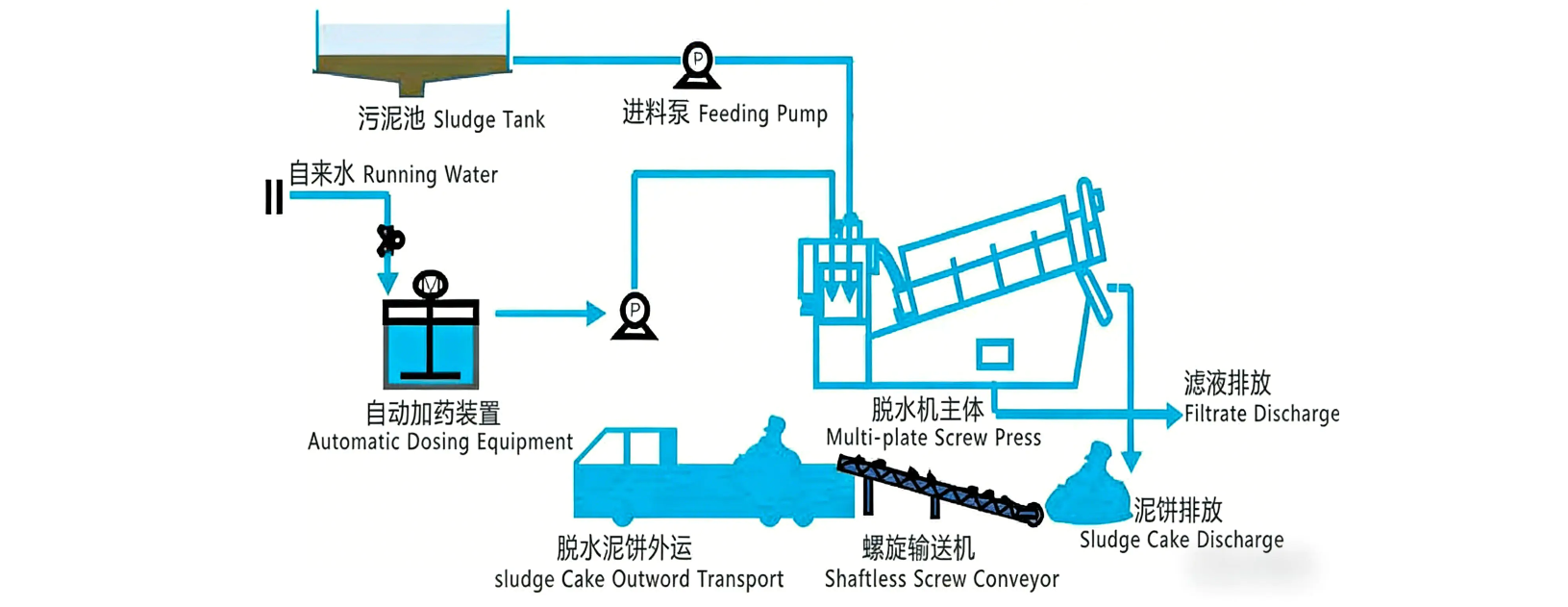

The operation of a screw press sludge dewatering machine involves several key steps:

- Sludge Feeding: The sludge is introduced into the screw press unit through a feed hopper. The sludge is typically pre-treated to reduce its viscosity and make the dewatering process more efficient.

- Compression and Dewatering: As the sludge moves through the rotating screw, it is gradually compressed. The screw's helical design forces the sludge through a perforated cylinder, allowing the water to escape while the solids remain behind.

- Water Removal: The water is expelled from the sludge and flows out through the perforated sections, often collected in a drainage system. The solidified sludge is then discharged at the machine's outlet.

- End Product: The end result is a significantly reduced volume of sludge, which is easier to handle, transport, or dispose of. The dewatered sludge can be used for composting, incineration, or landfilling, depending on the application.

Benefits of Using a Screw Press Sludge Dewatering Machine

Screw press sludge dewatering machines offer numerous advantages that make them a popular choice in wastewater treatment processes:

- Efficient Dewatering: These machines are highly effective at removing water from sludge, with the ability to achieve a dryness content of up to 30% depending on the sludge type.

- Low Energy Consumption: Compared to other dewatering methods, screw presses use less energy, making them an environmentally friendly and cost-effective option.

- Compact Design: Screw press units are generally compact and easy to install, making them suitable for facilities with limited space.

- Low Maintenance: These machines have fewer moving parts compared to other dewatering equipment, resulting in reduced maintenance and longer operational lifespans.

- Consistent Performance: Screw presses provide consistent and reliable performance, ensuring that the dewatering process runs smoothly and efficiently.

Applications of Screw Press Sludge Dewatering Machines

Screw press sludge dewatering machines are widely used in various industries where sludge management is a critical part of the wastewater treatment process. Some key applications include:

- Municipal Wastewater Treatment: These machines are commonly used in municipal treatment plants to process sewage and wastewater, reducing the volume of sludge for easier disposal or further treatment.

- Industrial Wastewater Treatment: Industries such as food processing, chemical manufacturing, and paper mills use screw press systems to handle their wastewater sludge efficiently and safely.

- Sludge Composting: Dewatered sludge can be used for composting purposes, where it is mixed with other organic materials to produce valuable compost for agricultural applications.

- Landfill and Incineration: After dewatering, the compacted sludge can be sent to landfills or incineration plants, reducing the environmental impact of sludge disposal.

How to Choose the Right Screw Press Sludge Dewatering Machine

When selecting a screw press sludge dewatering machine, it's essential to consider the following factors to ensure it meets your needs:

- Sludge Characteristics: The type, viscosity, and solids content of the sludge will determine the appropriate model and specifications of the screw press.

- Capacity: Choose a machine that can handle the required flow rate or volume of sludge produced by your facility. Ensure that the system is scalable if future expansion is planned.

- Maintenance Requirements: Consider the machine's maintenance needs, including ease of cleaning, availability of spare parts, and overall durability.

- Automation and Control Features: Modern screw press units come with automated control systems that allow for remote monitoring, improving efficiency and reducing the need for manual intervention.

FAQ

1. How much water can a screw press sludge dewatering machine remove?

A screw press sludge dewatering machine can typically remove up to 70-80% of the water content in the sludge, depending on the type of sludge and operating conditions. The exact percentage will vary.

2. How often does the screw press need maintenance?

Screw press machines require minimal maintenance, typically involving regular cleaning, checking for wear on the screw and other parts, and ensuring proper lubrication. Maintenance intervals can range from weekly to monthly, depending on usage.

While routine maintenance is important, you might also be interested in learning how to extend the lifespan of the screw conveyor during operation.

3. Can screw press machines be used for all types of sludge?

While screw press machines are versatile, they may not be suitable for extremely thick or highly viscous sludge without proper pre-treatment. It’s essential to assess the specific characteristics of your sludge before choosing the right dewatering solution.