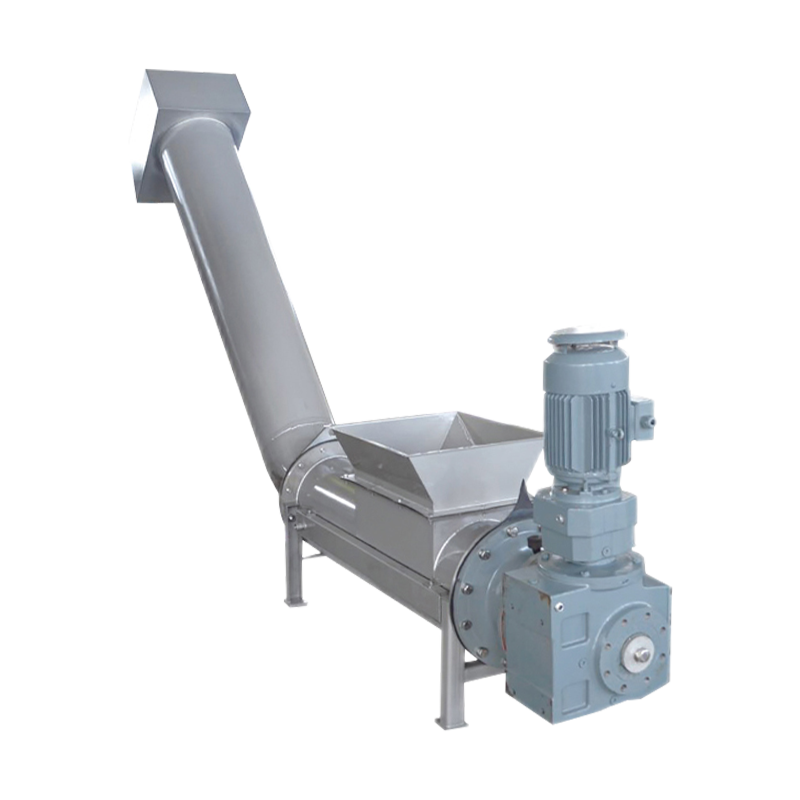

As an indispensable supporting equipment in the sewage treatment system, the screw press has shown significant application value in the field of screen residue treatment with its technical characteristics of efficient dehydration and intelligent integration. The screw press is a supporting equipment for the sewage screen, which consists of a feed hopper, a pressing screw, a spiral tube, a residue tube, a driver, etc., and plays a key role in the pretreatment of urban sewage treatment plants, industrial wastewater treatment plants and water plants.

The core structure of the equipment consists of a feed hopper, a pressing screw, a spiral tube, a residue tube and a drive device. After the screen residue or filter residue intercepted by the screen enters the spiral tube through the feed hopper, a progressive extrusion process is formed under the rotation of the shaftless screw. The screw press uses a shaftless screw, which has a small contact surface with the material and low friction, which can improve the extrusion efficiency. The water released during the extrusion process enters the water receiving basin through the filter mesh holes on the spiral tube wall, and flows back to the treatment system through the drain pipe. The material is discharged through the residue tube after compression, which can greatly reduce the weight and volume of debris such as screen scum.

This technology integration that combines mechanical engineering, materials science and intelligent control not only reconstructs the process flow of screen residue treatment, but also provides an innovative solution for improving the quality and efficiency of sewage treatment systems with a stable dehydration rate.