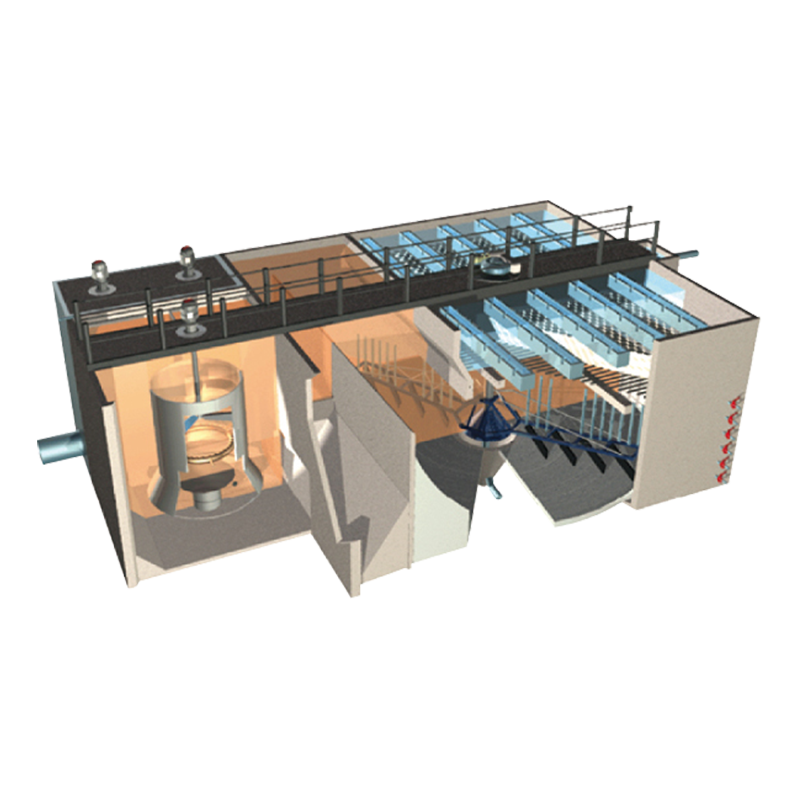

GMG High Density Sedimentation Tank Scraper is one of the core equipment in modern water treatment process. It integrates key technologies such as efficient mixing, flocculation, clarification and sludge concentration. In particular, it occupies an important position in the field of water treatment with the characteristics of "high separation efficiency, small mud and water volume, and small footprint". As a key component of the high-density clarification tank system, the equipment significantly improves the operating efficiency of the sedimentation tank through continuous sludge scraping and intelligent control technology, and shows wide applicability in scenarios such as drinking water purification, municipal sewage treatment, industrial wastewater treatment and sludge disposal.

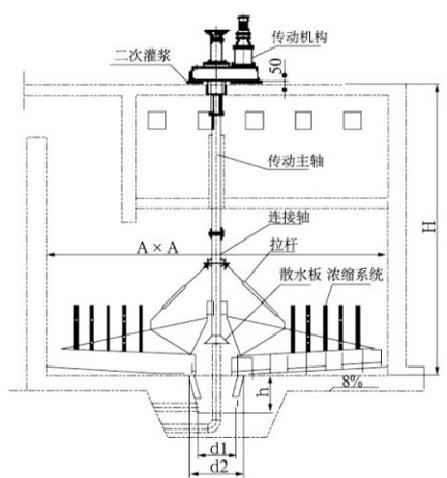

The process advantage of the high-density sedimentation tank comes from its multi-stage collaborative design architecture. In the mechanical mixing area, the stirring device fully mixes the influent with the coagulant and flocculant to quickly form dense alum flowers, which then enter the flocculation reaction area and strengthen the floc growth through the stirring mode with decreasing energy gradient to form particles that are easy to precipitate. The core innovation of the GMG scraper lies in its precise control of sludge return. The system can adjust the external sludge return ratio, which can not only avoid the decline of flocculation effect due to insufficient return, but also prevent the disturbance of the sedimentation area caused by excessive return sludge.

GMG high-density sedimentation tank scraper has high surface load and small footprint. Through sludge circulation and polymer addition, the surface load can reach 15-25m3/(m2h). These technical characteristics make GMG scraper an important carrier to promote the transformation of water treatment process to intensive and intelligent, and provide reliable technical support for the recycling of water resources.