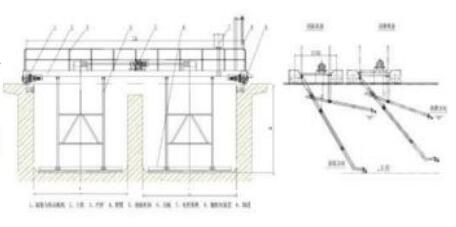

HJG truss mud scraper adopts a reciprocating action to scrape the bottom mud to one end of the mud collection pit and discharge it for the sludge scraping at the bottom of the horizontal sedimentation tank. One end of the sludge is fed into the water and the other end is discharged. The bottom of the pool has a certain slope (about 8/1000). The gauge is generally about 4-25m, when the pool width is larger, it can be made into a multi-pool structure, and the gauge 4-8m is generally a single drive.