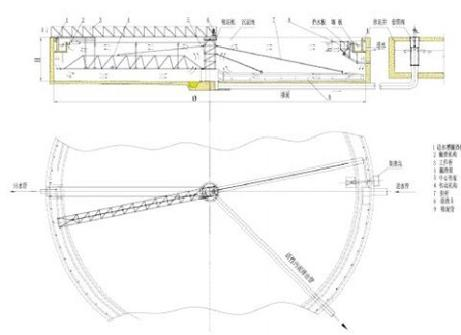

The Center Drive Single Tube Suction Dredger generally adopts peripheral water inlet and peripheral water outlet. The sludge is sucked to the center of the pool by a single or double tube and then discharged by the mud valve outside the pool. It can be equipped with a scraper device (including a water distribution tank). Generally, inert sludge and activated sludge can be collected in layers and then discharged outside the pool. By optimizing the hydraulic model and mechanical transmission system, a double breakthrough in sedimentation efficiency and operation stability is achieved. It is especially suitable for sedimentation tanks with peripheral water inlet and peripheral water outlet, and has become a key equipment for sludge collection in municipal sewage plants and industrial wastewater treatment projects.

The innovation of this equipment is first reflected in the systematic optimization of the hydraulic model. Through numerical simulation and fluid dynamics verification, the water distribution system of the sludge suction machine adopts a non-uniformly distributed hole distribution design, so that the water flow forms a stable radial flow pattern in the pool. The synergistic effect of the peripheral water inlet and the water outlet weir plate not only avoids the short-circuit phenomenon, but also strengthens the sludge sedimentation effect by adjusting the liquid level difference, significantly improving the sedimentation efficiency. The central pier of the product serves as the core supporting structure, which reduces the construction difficulty and ensures the spatial positioning accuracy of the drive shaft and the sludge suction pipe through precision machining.

At the mechanical structure level, the design of the vertical frame suction pipe reflects the balance between lightness and rigidity. The suction pipe adopts a variable cross-section structure, and suction ports of different apertures are set along the radius of the pool. Combined with the scraper auxiliary disturbance device, it realizes the full coverage of sludge collection from the edge of the pool to the center of the pool. The central drive single-tube suction machine uses a vertical frame suction pipe, which has a reasonable weight and runs smoothly and reliably.

With the improvement of energy efficiency and intelligent requirements for sewage treatment processes, the central drive single-tube suction machine is developing towards modularization and Internet of Things integration.