Peripheral Drive Mud Scraper is mainly used for large-scale, generally top-free scraping pool system, with pool scraping and slag scraping functions, and the process is generally central water inlet. Through the process layout of central water inlet and peripheral drainage, an efficient hydraulic flow pattern is constructed to achieve simultaneous treatment of sludge and scum, which becomes a key link in improving the stability of sewage treatment system.

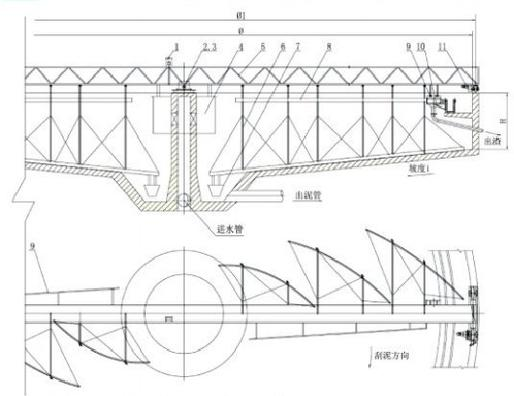

From the perspective of structural design, the innovation of peripheral drive scraper is reflected in multi-dimensional technology integration. Its core working bridge adopts a truss beam structure. Through lightweight materials and mechanical optimization design, it greatly reduces its own weight while ensuring rigidity. The length of the bridge body can be flexibly adjusted according to the pool diameter.

The process efficiency of the equipment is closely related to its hydraulic model. The central water inlet cooperates with the guide tube to form a stable radial water flow. The suspended sludge settles evenly under the action of gravity, and the supernatant is discharged, forming a gradient sedimentation process from the center to the periphery. The scraper mechanism rotates slowly around the pool, and pushes the bottom sludge layer by layer to the central sludge collecting bucket through the vertically erected scraper arm. At the same time, the floating slag on the liquid surface is synchronously collected by the rotating skimming plate to the slag discharge bucket, realizing the coordinated operation of scraping and slag removal. Compared with traditional scraper equipment, it can withstand axial force and radial torque through the precise coordination of the slewing bearing and the central pier, and can also achieve mechanical overload protection through the torque limiter. When the operating resistance exceeds the preset threshold, the power is automatically cut off, effectively reducing the equipment failure rate and maintenance cost.

This technology integration that combines mechanical engineering and intelligent control is providing more competitive solutions for urban water environment management and industrial clean production.