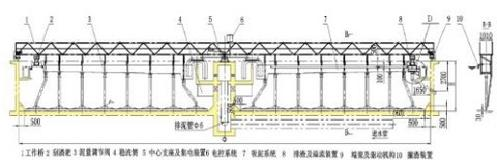

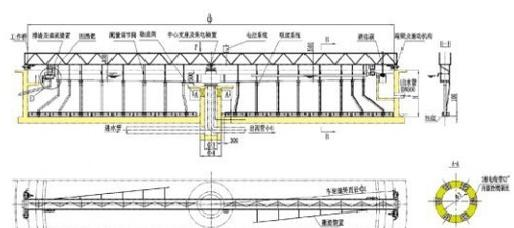

The Peripheral Drive Mud Suction Machine is an indispensable key equipment in sewage treatment projects. It is generally used in radial flow sedimentation tanks of large-scale (generally refers to flow rates greater than 500m3/h) sewage treatment projects. It is particularly suitable for scraping and discharging sludge at the bottom of the secondary sedimentation tank. The tank shape generally adopts central water inlet, peripheral water outlet, and central sludge discharge, and no slope is required at the bottom of the tank.

In the secondary sedimentation tank, the peripheral transmission sludge suction machine drives the main beam to rotate around the center of the tank through the drive device, and the bottom sludge scraper continuously scrapes the deposited sludge to the central sludge collection area. In response to the sludge discharge needs of different scenarios, the equipment is designed with two mainstream sludge discharge modes: static pressure sludge discharge and siphon sludge discharge. Static pressure sludge discharge relies on the principle of liquid level difference. The sludge is controlled by the regulating valve of each sludge suction pipe and directly enters the central sludge tank and is discharged. Siphon sludge discharge relies on the vacuum pump to start the siphon effect, and the sludge is sucked into the sludge discharge pipe through secondary lifting. It is suitable for scenes where there is a height difference between the pool bottom and the sludge discharge port. Its advantage is that it can overcome large resistance and ensure the continuity and stability of sludge discharge.

To address the problem of torque fluctuation under complex working conditions, modern peripheral transmission sludge suction machines are often equipped with shaft-mounted reducers and integrated over-torque protection devices. When the equipment encounters obstacles or sludge resistance surges during operation, the sensor will monitor the torque change in real time. Once it exceeds the set threshold, it will trigger an alarm and shut down, which not only protects the mechanical structure from damage, but also avoids the risk of motor overload, and improves the safety and durability of the system.

These technological innovations enable peripheral transmission sludge suction machines to improve sewage treatment efficiency while taking into account energy saving and consumption reduction and convenient operation and maintenance, making them an indispensable core equipment in modern sewage treatment processes.